What would be the demand for the plastics for electric vehicle at region/ country level?

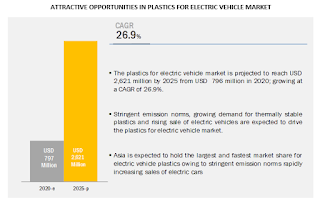

The Plastic

for Electric Vehicle Market is projected to grow at a CAGR of 26.9% to

reach a market size of USD 2,621 million by 2025 from 797 million in 2020. The

stringent emission standards coupled with automakers focus on weight reduction

is driving the demand of plastics in electric vehicles. Additionally, the OEMs

inclination towards thermally stable plastics is further anticipated to drive

the demand of plastic in electric vehicles.

To cater

OEM demands, the plastic suppliers are developing plastics for electric

vehicles which are efficient and lighter in weight. These developments are

mainly focused on light weight and high tensile strength of the platsic. For

instance, BASF presented prototypes of the world's first particle foam

based on polyethersulfone (PESU). The foam is characterized by its unique

combination of properties like high-temperature resistance, inherent flame

retardancy, and its extreme light weight, great stiffness and strength. It is

therefore particularly well suited for complex-shaped components in cars,

airplanes, and trains, which require

excellent mechanical properties together with the ability to withstand high

operating temperatures or meet stringent flame-retardant requirements. Thus,

development of plastics in sync with the OEMs and the component manufacturer’s

demand is anticipated to create lucrative growth opportunities.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=219387183

BEV

segment is estimated to be the largest and fastest growing market by vehicle

type in plastics for electric vehicle market. Due to stringant emission

regulation and government pushing towards electric mobility are the

major factors driving the plastics for electric vehicle. Also, BEV

manufacturers are working on reducing their overall weight, which will allow to increase the power of

electric vehicle, and result in extend range of electric vehicle. To reduce the

weight of the vehicle automotive OEMs are focusing on metal to plastic

conversion and injection moulded plastic parts. Furthermore, OEMS are also,

focusing on strength and safety, lower cost and suitable plastics with high

temperature resistive property for battery compartment area. This trend

is likely to create new opportunities for the plastic supplier, which are lighter

in weight and comparatively less expensive than metal components.

According to

MarketsandMarkets, Asia is estimated to be the largest and fastest-growing

market for plastics for electric vehicles in the forecasted period, 2020-2025. The primary reason for this growth is due to

attractive government schemes and policies for promoting electric vehicle.

Also, implementation of stringent emission standards like China 6a, BS-VI is

expected to boost BEV sales which in turn increases demand for plastics for

electric vehicle. Also, the presence of numerous players in the region paves

the way for continuous developments for

high temperature resistive and high performance plastics which in turn

is likely to drive the plastics for electric vehicle market in the region.

Thus, with increasing sales of

electric vehicles globally, increasing demand for light weight materials and

stringent emission norms, the plastics for electric vehicle market is expected

to witness significant growth during the forecast period. Additionally,

continuous developments in plastics for electric vehicle, including high

tensile strength, thermally stable plastics are also likely to further fuel the

demand.

Request Free Sample

Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=219387183

Key Market Players

Some of the key players in the plastics for electric

vehicle market is dominated by global players and comprise several regional

players. The key players in the plastics for electric vehicle market are BASF

(Germany), SABIC (Saudi Arabia), Dow (US), Lyondellbasell Industries Holdings

B.V (Netherlands), DuPont de Nemours, Inc.(US), Covestro (Germany), Solvay

(Belgium), LANXESS (Germany), LG Chem (South Korea), Asahi Kasei (Japan) has

adopted the strategies of expansion and partnerships to retain its leading

position in the plastics for electric vehicle market.

Key Questions Addressed

by the Report

·

What

would be the demand for the plastics for electric vehicle at region/ country

level?

·

How

will the plastics for electric vehicle market shape up in the future?

·

What

are the current and future trends in the plastics for electric vehicle market?

·

How

the penetration of plastics by application type varies by region?

·

Which

are the key players in the plastics for electric vehicle market?

To speak to our analyst

for a discussion on the above findings, click Speak

to Analyst

Comments

Post a Comment